About usProducts

CatalogDocumentsFor DealersContacts

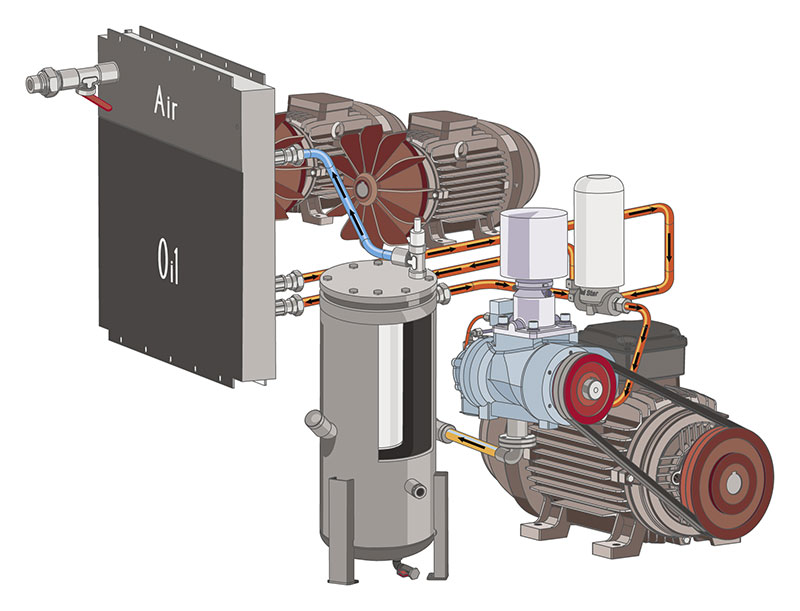

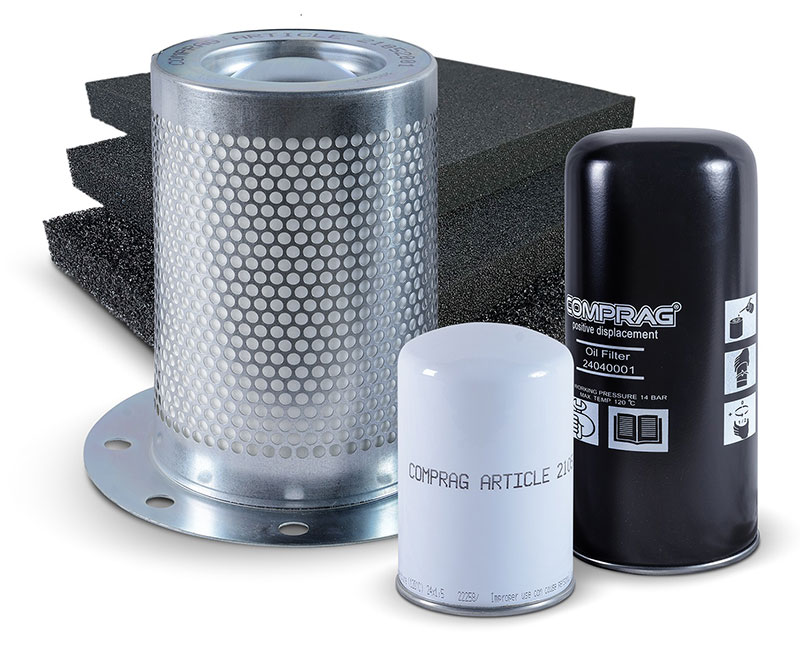

Screw compressors by design/configuration

Freestanding screw compressors

Screw compressors on air receiver (tank)

Screw compressors on air receiver (tank), refrigerant dryer

Screw compressor by drive power

Screw compressor, drive power 5.5-7.5 kW

Screw compressor, drive power 11-15 kW

Screw compressor, drive power 18.5-22 kW

Screw compressor, drive power 30-37 kW

Screw compressor, drive power 45-55 kW

Screw compressor, drive power 75-90 kW

Belt-driven fixed speed screw compressor by capacity

Belt-driven fixed speed screw compressor, capacity 0.55 - 1.1 m3/min

Belt-driven fixed speed screw compressor, capacity 1.3 - 2.3 m3/min

Belt-driven fixed speed screw compressor, capacity 2.2 - 3.6 m3/min

Belt-driven fixed speed screw compressor, capacity 3.7 - 6.5 m3/min

Belt-driven fixed speed screw compressor, capacity 5.7 - 9.0 m3/min

Belt-driven fixed speed screw compressor, capacity 9.2 - 14.7 m3/min

Direct-drive fixed speed screw compressor by capacity

Direct-drive fixed speed screw compressor, capacity 1.3 - 2.3 m3/min

Direct-drive fixed speed screw compressor, capacity 2.6 - 3.6 m3/min

Direct-drive fixed speed screw compressor, capacity 4.6 - 6.2 m3/min

Direct-drive fixed speed screw compressor, capacity 6.6 - 9.6 m3/min

Direct-drive fixed speed screw compressor, capacity 11.3 - 15.4 m3/min

Belt-driven variable speed (VSD) screw compressor by capacity

Belt-driven variable speed screw compressor, capacity 3.7 - 6.2 m3/min

Belt-driven variable speed screw compressor, capacity 5.7 - 9.0 m3/min

Belt-driven variable speed screw compressor, capacity 9.2 - 14.7 m3/min

Direct-drive variable speed (VSD) screw compressor by capacity

Direct-drive variable speed screw compressor, capacity 1.3 - 2.3 m3/min

Direct-drive variable speed screw compressor, capacity 2.6 - 3.6 m3/min

Direct-drive variable speed screw compressor, capacity 4.6 - 6.2 m3/min

Direct-drive variable speed screw compressor, capacity 6.6 - 9.6 m3/min

Direct-drive variable speed screw compressor, capacity 11.3 - 15.4 m3/min

Compressed air refrigeration dryers by volume flow

Refrigeration dryers, volume flow 0.4 - 1.8 m3/min

Refrigeration dryers, volume flow 2.4 - 4.1 m3/min

Refrigeration dryers, volume flow 5.2 - 7.7 m3/min

Refrigeration dryers, volume flow 10.0 - 18.0 m3/min

Refrigeration dryers, volume flow 20.0 - 36.0 m3/min

Compressed air refrigerated dryers by drive power

Refrigerated dryers, drive power 0.1-0.3 kW

Refrigerated dryers, drive power 0.5-0.8 kW

Refrigerated dryers, drive power 1.0-1.5 kW

Refrigerated dryers, drive power 2.1-3.0 kW

Refrigerated dryers, drive power 3.0-5.4 kW

Compressed air refrigeration dryers by thread connection

Refrigerated dryers, thread connection 1/2"

Refrigerated dryers, thread connection 3/4"

Refrigerated dryers, thread connection 1"

Refrigeration dryers, thread connection 1.1/2"

Refrigeration dryers, thread connection 2.1/2"

Refrigeration dryers, flange DN80

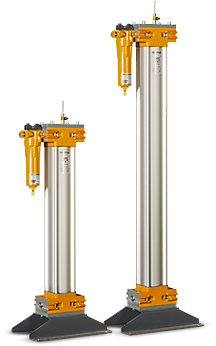

Adsorption dryers by construction

Modular adsorption dryer

Adsorption dryer, two pressure vessels

Adsorption dryers by series

Modular adsorption dryers ADM, fixed cycle times

Modular adsorption dryers ADM-PDP, pressure dew point control

Adsorption dryers ADX-F, fixed cycle times

Adsorption dryers ADX-F-PDP, pressure dew point control

Adsorption dryers by volume flow

Adsorption dryer ADM, fixed cycle times, volume flow 0.5 - 1.5 m3/min

Adsorption dryer ADM-PDP, pressure dew point control, volume flow 0.5 - 1.5 m3/min

Adsorption dryer ADX-F, fixed cycle times, volume flow 2.0 - 4.0 m3/min

Adsorption dryer ADX-F, fixed cycle times, volume flow 5.0 - 9.0 m3/min

Adsorption dryer ADX-F, fixed cycle times, volume flow 12.5 - 25.0 m3/min

Adsorption dryer ADX-F-PDP, pressure dew point control, volume flow 2.0 - 4.0 m3/min

Adsorption dryer ADX-F-PDP, pressure dew point control, volume flow 5.0 - 9.0 m3/min

Adsorption dryer ADX-F-PDP, pressure dew point control, volume flow 12.5 - 25.0 m3/min

Adsorption dryers by threaded connection

Adsorption dryer ADM, fixed cycle times, threaded connection 1/2"

Adsorption dryer ADM-PDP, pressure dew point control, threaded connection 1/2"

Adsorption dryer ADX-F, fixed cycle times, threaded connection 1"

Adsorption dryer ADX-F, fixed cycle times, threaded connection 1.1/4"

Adsorption dryer ADX-F, fixed cycle times, threaded connection 1.1/2"

Adsorption dryer ADX-F, fixed cycle times, threaded connection 2"

Adsorption dryer ADX-F, fixed cycle times, threaded connection 2.1/2"

Adsorption dryer ADX-F-PDP, pressure dew point control, threaded connection 1"

Adsorption dryer ADX-F-PDP, pressure dew point control, threaded connection 1.1/4"

Adsorption dryer ADX-F-PDP, pressure dew point control, threaded connection 1.1/2"

Adsorption dryer ADX-F-PDP, pressure dew point control, threaded connection 2"

Adsorption dryer ADX-F-PDP, pressure dew point control, threaded connection 2.1/2"

Activated carbon adsorbers by construction

Activated carbon adsorber in modular design

Activated carbon adsorbers by series

Activated carbon adsorber ACT

Activated carbon adsorbers by volume flow

Activated carbon adsorber ACT, volume flow 0.5 - 6.0 m3/min

Adsorption dryers by threaded connection

Activated carbon adsorber ACT, threaded connection 1/2"

Activated carbon adsorber ACT, threaded connection 1.1/2"

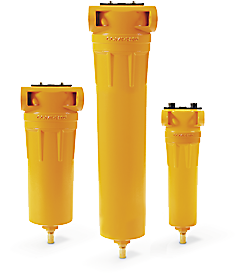

Compressed air filters by filtration grade

Air filter, filtration grade P

Air filter, filtration grade M

Air filter, filtration grade S

Air filter, filtration grade A

Compressed air filters by description

Air filter dust filter

Air filter coalescing filter coarse

Air filter coalescing filter fine

Air filter activated carbon filter

Compressed air filters by use/application

Air filter, residual particle size 5 µ

Air filter, residual particle size 0.1 µ

Air filter, residual particle size 0.01 µ

Air filter, oil content (total concentration) < 0.005 mg/m3

Compressed air filters by threaded connection

Air filter, threaded connection 3/8"

Air filter, threaded connection 1/2"

Air filter, threaded connection 3/4"

Air filter, threaded connection 1"

Air filter, threaded connection 1.1/4"

Air filter, threaded connection 1.1/2"

Air filter, threaded connection 3"

Cyclone condensate separators by series

Cyclone condensate separator DFS

Cyclone condensate separators by volume flow

Cyclone condensate separator DFS, volume flow 1.2 - 36.0 m3/min

Cyclone condensate separators by threaded connection

Cyclone condensate separator DFS, threaded connection 3/8"

Cyclone condensate separator DFS, threaded connection 1/2"

Cyclone condensate separator DFS, threaded connection 3/4"

Cyclone condensate separator DFS, threaded connection 1"

Cyclone condensate separator DFS, threaded connection 1.1/4"

Cyclone condensate separator DFS, threaded connection 1.1/2"

Cyclone condensate separator DFS, threaded connection 3"

Compressed air tanks by design

Compressed air tank powder-coated externally

Compressed air tank hot-dip galvanized internally/externally

Compressed air tanks by volume

Compressed air tank, volume 500 liters

Compressed air tank, volume 1000 liters

Compressed air tank, volume 1500 liters

Compressed air tank, volume 2000 liters

Compressed air tank, volume 3000 liters

Compressed air tanks by safety valve

Compressed air tank, safety valve 1/2" (3.6 m3/min)

Compressed air tank, safety valve 3/4" (12 m3/min)

Compressed air tank, safety valve 1" (16 m3/min)

Condensate drain valves by series

Timed drain valve TD

Mechanical float drain valve FD

Electronic level-controlled condensate drain valve ED

Condensate drain valves by operating principle

Condensate drain valves, pressure loss

Condensate drain valves without pressure loss

Int/En

Int/En