Cyclone separators DFS-series

Cyclone separators for compressed air lines DFS-series

Specifications

| Model | DFS-012 - DFS-360-Twin |

| Air flow (m3/min) | 1,2 - 36,0 |

| Screw connection | 3/8" - 3" |

| Weight (kg) | 0,7 - 13,5 |

DFS-series Separators supplied ready-to-use, assembled with a separation element, and are a reliable and cost effective method of removing liquid condensate from compressed air. Modular construction. New filter head design enables in-line installation of filters and separators to achieve the required ISO filtration class according to ISO 8573-1:2010.

Standard delivery:

Internal automatic drain valve.

To be preceded by:

Compressed air aftercooler.

Separators specification

| Grade | - |

| Operating principle | Centrifugal separation |

| Separation grade by water content in liquid phase, % | >99% |

| Maximum operating temperature, °C | 65 |

| Pressure loss at nominal air flow, mbar | 55 |

- Efficient removal of condensate and 99% of particles

- Removes condensate and particulates down to 5 microns

- Maximum operating pressure of 16 bar

- Operating temperature range 2 °C - 60 °C

- Wide range of thread sizes from 3/8" to 3"

Separating element

Unique centrifugal separating element with modern design and minimal pressure loss: efficient removal 99% of fluid condensate, optimal for use with variable speed compressors - full degree of separation between 20% and 120% of the flow rate, no replacement components required, reliable sealing with O-rings.

Drain valve

Built-in reliable maintenance-free float drain valve.

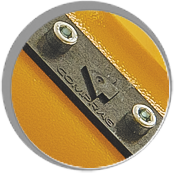

Air flow direction arrow

Air flow direction arrow for correct installation in the compressed air line.

Optional equipment

WIN - water presence indicator.