Screw compressors FV-Serie

capacity up to 9,0 m3/min

Specifications

| Model | FV-45 | FV-55 |

| Drive power (kW) | 45,0 | 55,0 |

| Working pressure (bar) | 5-8 / 5-10 | 5-8 / 5-10 |

| Max. capacity* (m3/min) | 7,5 / 6,5 | 9,0 / 7,9 |

| Rated voltage (Phase/V/Hz) | 3/380-420/50 | 3/380-420/50 |

| Sound pressure level** dB(A) | 75 | 75 |

| Screw connection | 1 1/2" | 1 1/2" |

| Length L (mm) | 1650 | 1650 |

| Width W (mm) | 1250 | 1250 |

| Height H (mm) | 1720 | 1720 |

| Weight (kg) | 1015 | 1190 |

* Measured according to ISO 1217

** Measured according to ISO 3744

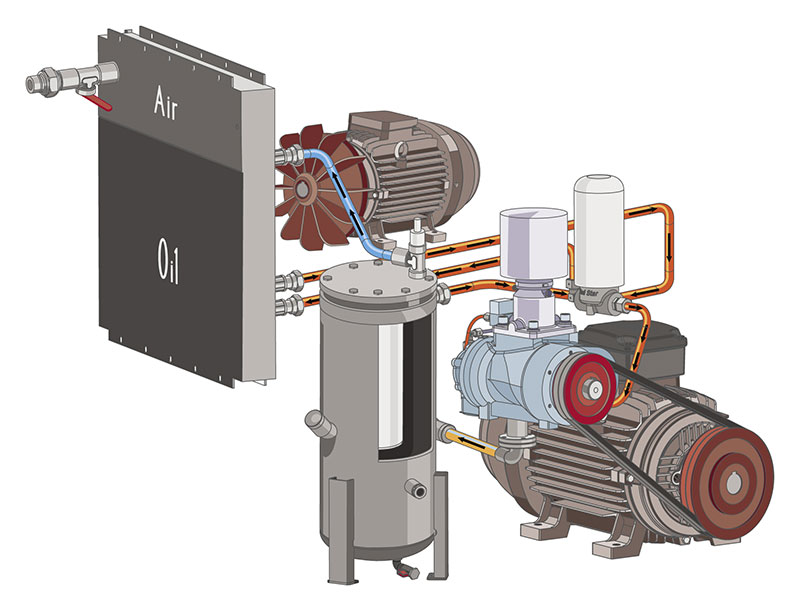

Comparg FV-Series oil filled screw compressors are designed for smooth and economical production of compressed air in industrial plants.They feature a compact logically laid-out design, high quality materials and workmanship, and key components from leading manufacturers.

Features

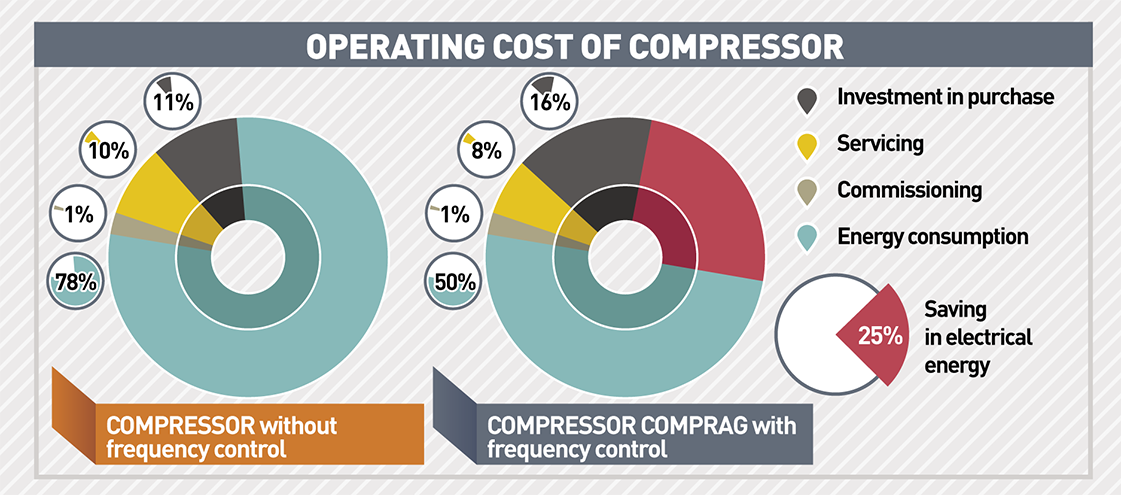

FV-Series compressors have been developed to offer an optimal balance between performance, energy saving solutions, and offer increased servicing intervals to reduce your running costs. FV-Series compressors are most efficient in class.

- Low operating cost

- Only as much electrical energy is required as compressed air

- No electrical energy consumption during idling

- Constant system pressure

- No loading/unloading modes

- No pulsation and pressure drops

- Low maximum system pressure

- Less compressed-air leakage

- Conserved electrical energy owing to no excess pressure in system

FV-series frequency control

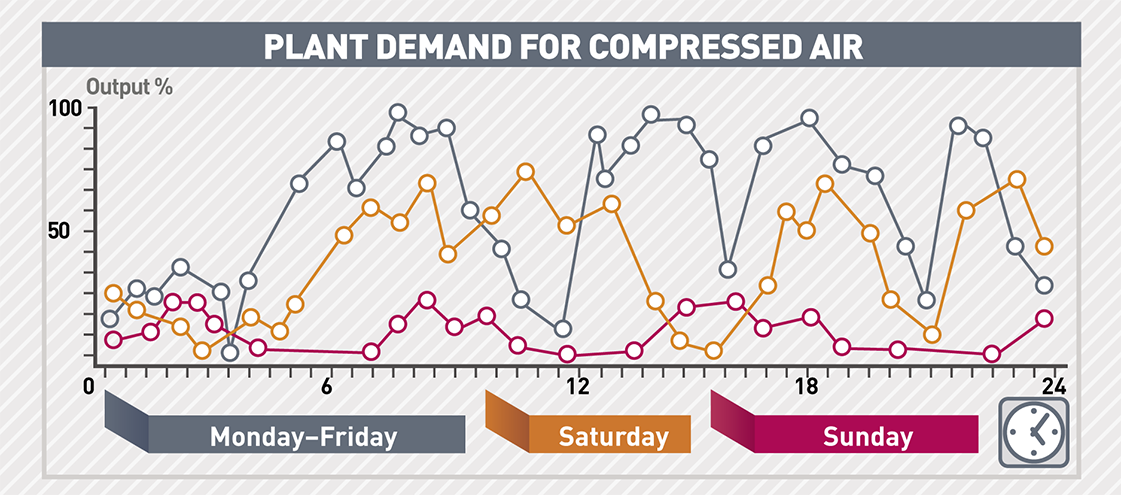

A plant's demand for compressed air varies throughout the day - from zero demand to peak demand.

Conventional screw compressors are not able to switch between operating modes according to a plant's current demand for compressed air. Owing to constant switching between loading/unloading modes or the idle running of compressors, conventional screw compressors consume consistently large amounts of electrical energy when operating.

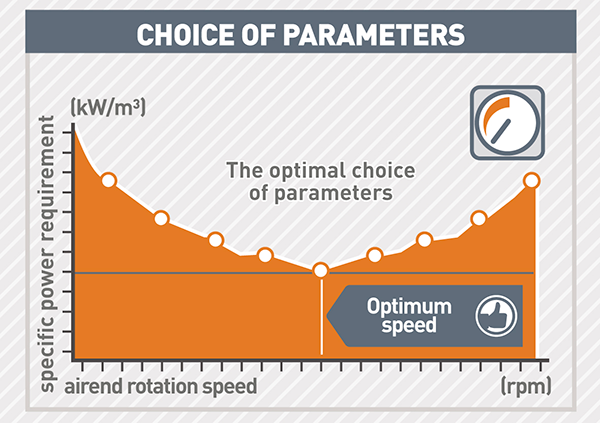

The Comprag FV compressor series with frequency control has been created for economical compressor operation where there is varying demand.

FV compressors are provided with a frequency converter for continuous control of compressor output according to the current demand for compressed air. They provide a plant with the necessary amount of compressed air at a given moment and at a constant set pressure, while consuming only as much electrical energy as there is demand for compressed air. This mode of operation conserves as much energy as possible.

Comprag compressors with frequency control allow a 25% saving in electrical energy consumption.

Mechanism of compressor with frequency control:

Varying compressed-air demand involves a change in pressure in a plant's compressed-air system. A pressure sensor installed in the compressor brings about a change in system pressure by means of a corresponding signal sent to the compressor's controller. Via the frequency converter, the controller sets a speed for the electric motor to match the compressor's required output. In this way, the plant's compressed-air system pressure is kept at a constant value.

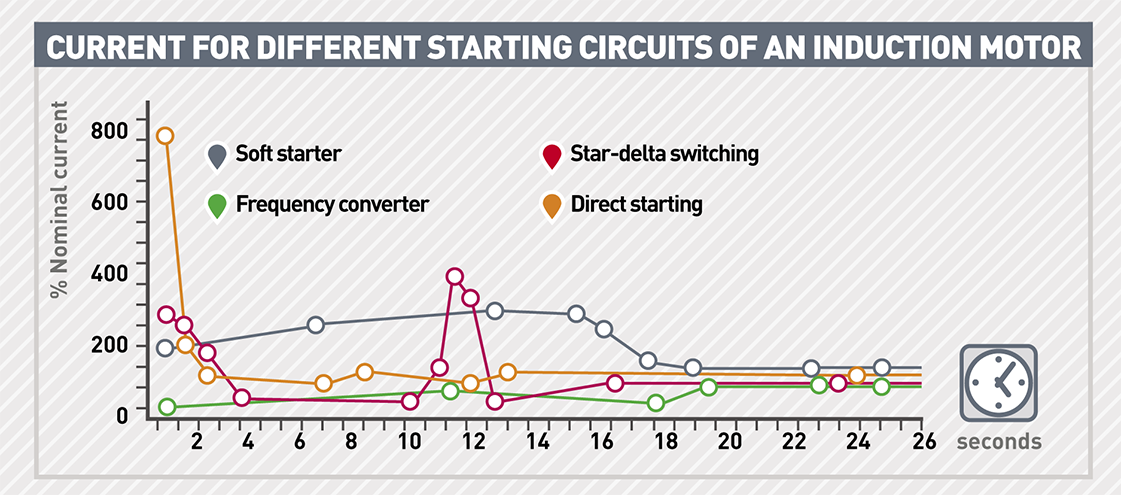

The frequency converter means that compressor start-up is associated with very low starting currents. This has a positive effect on the service life of the electrical motor and the electrics.