Screw compressors DV-serie

capacity up to 9,6 m3/min

Specifications

| Model | DV-45 | DV-55 |

| Drive power (kW) | 45 | 55 |

| Working pressure (bar) | 8 / 10 | 8 / 10 |

| Max. capacity* (m3/min) | 7,0 - 6,2 | 9,1 - 8,5 |

| Rated voltage (Phase/V/Hz) | 3/380-420/50 | 3/380-420/50 |

| Sound pressure level** dB(A) | 75 | 75 |

| Screw connection | 1 1/2" | 1 1/2" |

| Length L (mm) | 1250 | 1250 |

| Width W (mm) | 1650 | 1650 |

| Height H (mm) | 1500 | 1500 |

| Weight (kg) | 1010 | 1175 |

* Measured according to ISO 1217

** Measured according to ISO 3744

DV-Series rotary screw oil-filled compressors feature high performance, reliability and efficiency. The screw unit has a direct one-to-one connection to the motor through a coupling and transfers the torque without loss, increasing the energy efficiency of the compressor in comparison with a belt or gear drive.

Features

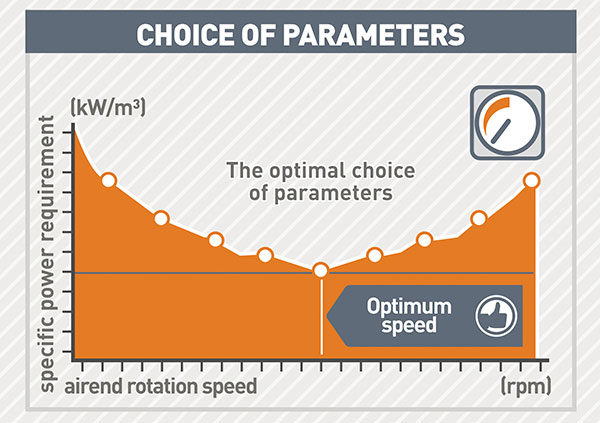

The rotation speed of the helical screw rotor unit is selected on the basis of the specific optimal performance. All compressor components have been designed according to parameters chosen for optimal performance and low operating costs. Comparg DV-Series offer some of the lowest specific production costs of compressed air.

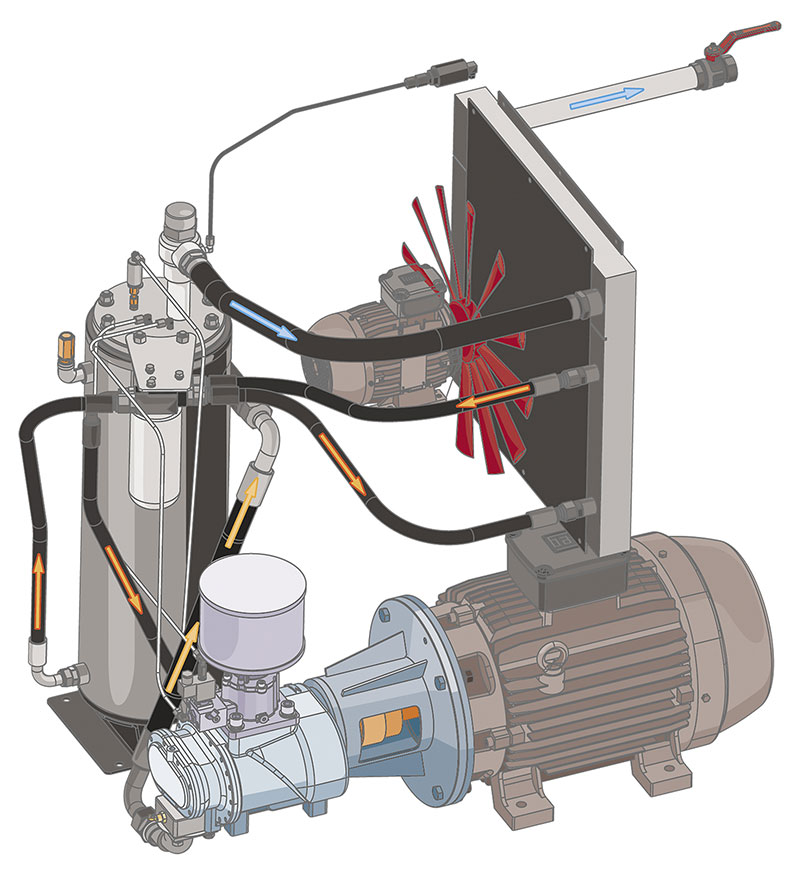

- Direct one-to-one drive. The large size of the screw unit and the low rotational speed of rotors extend the service life and reduce vibration and background noise.

- Efficient and quiet centrifugal radiator cooling fan. Centrifugal fans sustain constant pressure throughout the whole air-flow diameter. Thermal conductivity with the use of centrifugal fans is greater than that from the use of axial fans.

- The components of the compressor are connected using a metallic pipe arrangement or flexible metal hoses. This assembly method is more reliable and durable than the use of rubber hoses.

- The immediate pressure control function provides a fail-safe in the control system during start-up of the compressor.

- Easy access to the main compressor modules for servicing.

DV-series frequency control

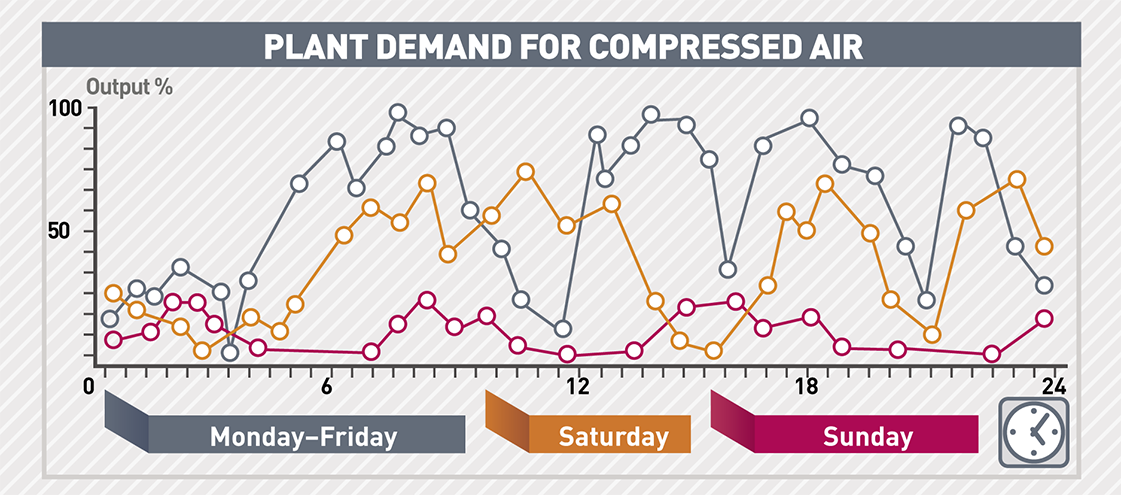

A plant's demand for compressed air varies throughout the day - from zero demand to peak demand.

Conventional screw compressors are not able to switch between operating modes according to a plant's current demand for compressed air. Owing to constant switching between loading/unloading modes or the idle running of compressors, conventional screw compressors consume consistently large amounts of electrical energy when operating.

The Comprag DV compressor series with frequency control has been created for economical compressor operation where there is varying demand.

DV compressors are provided with a frequency converter for continuous control of compressor output according to the current demand for compressed air. They provide a plant with the necessary amount of compressed air at a given moment and at a constant set pressure, while consuming only as much electrical energy as there is demand for compressed air. This mode of operation conserves as much energy as possible.

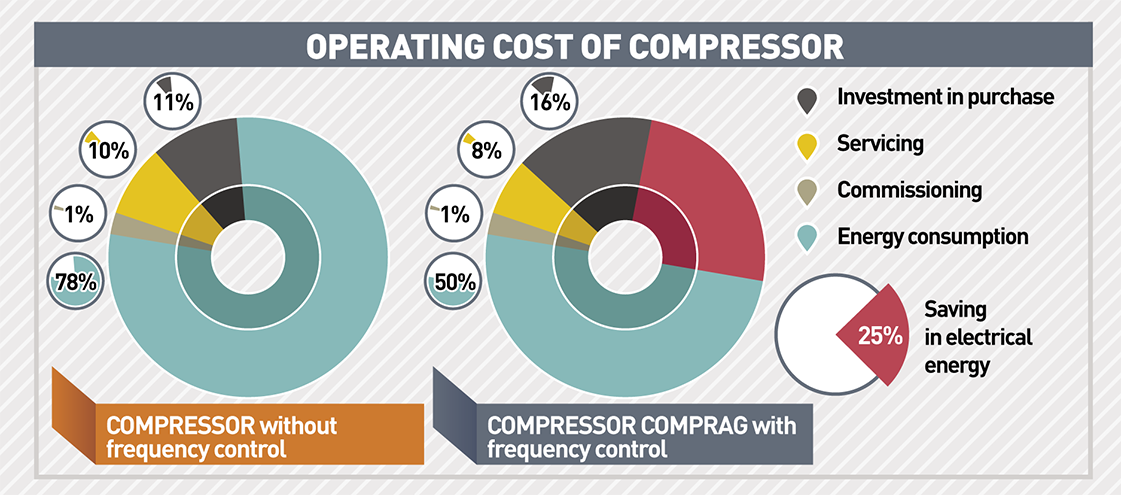

Comprag compressors with frequency control allow a 25% saving in electrical energy consumption.

Mechanism of compressor with frequency control:

Varying compressed-air demand involves a change in pressure in a plant's compressed-air system. A pressure sensor installed in the compressor brings about a change in system pressure by means of a corresponding signal sent to the compressor's controller. Via the frequency converter, the controller sets a speed for the electric motor to match the compressor's required output. In this way, the plant's compressed-air system pressure is kept at a constant value.

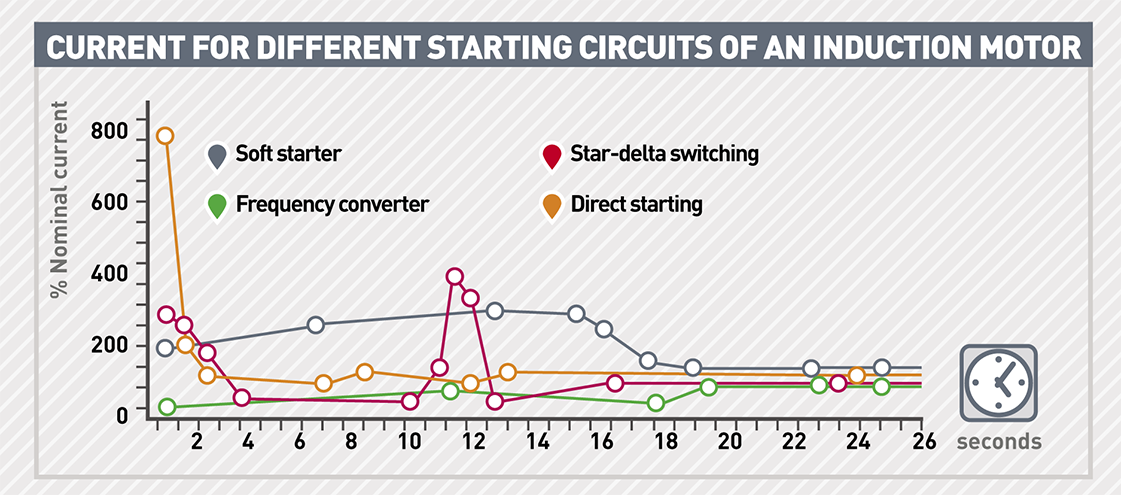

The frequency converter means that compressor start-up is associated with very low starting currents. This has a positive effect on the service life of the electrical motor and the electrics.